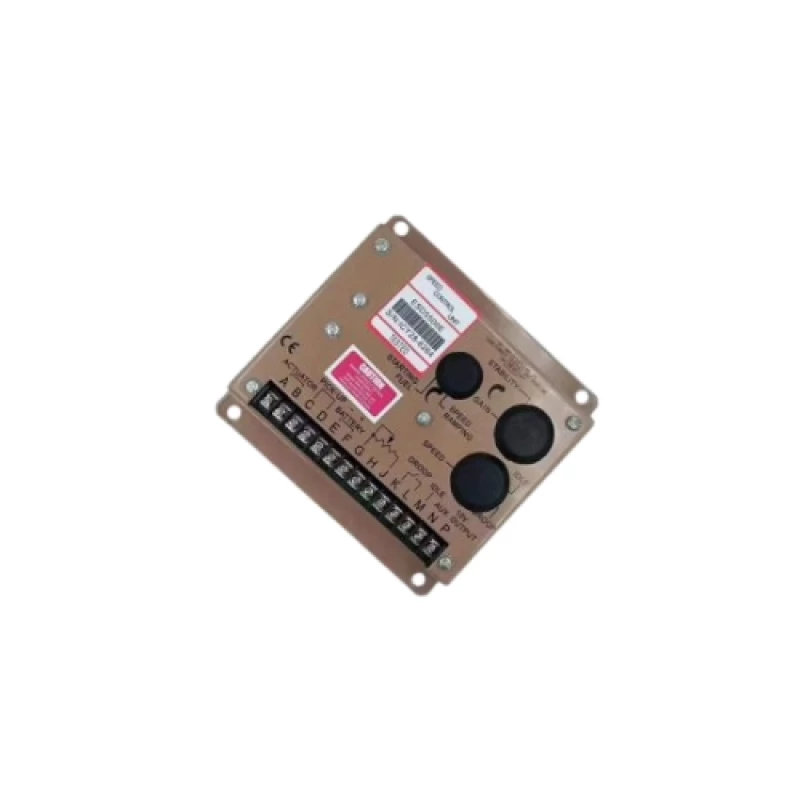

Quality Cummins Engine Speed Control (2) - MOQ 1 PC #Wholesaleprice#Africa

Nigeria

Nigeria

Key Features

- Contact seller for Quotation

- Cummins engines are equipped with an Electronic Control Module (ECM) that serves as the brain of the engine control system

- Cummins engines are equipped with speed sensors that continuously monitor the rotational speed of the engine

- Minimum order quantity 1 piece

Frequently bought together:

Cummins Engine Speed Control is a critical component in diesel engines that helps regulate and maintain the optimal operating speed of the engine. Controlling the engine speed is essential for ensuring efficient performance, fuel economy, and overall durability of the engine.

Electronic Control Module (ECM):

- Cummins engines are equipped with an Electronic Control Module (ECM) that serves as the brain of the engine control system. The ECM processes information from various sensors and uses algorithms to control critical engine parameters, including speed.

Speed Sensors:

- Cummins engines are equipped with speed sensors that continuously monitor the rotational speed of the engine. These sensors provide real-time data to the ECM, allowing it to make rapid adjustments to maintain the desired speed.

Actuators:

- Actuators are devices that respond to signals from the ECM by adjusting the engine components to achieve the desired speed. In the context of speed control, actuators may control fuel injection, air intake, or other parameters affecting engine speed.

Governors:

- Cummins Engine Speed Control systems often include governors, which are mechanical or electronic devices designed to regulate the speed of the engine. Governors can adjust the fuel delivery or airflow to maintain a consistent speed under varying load conditions.

Cruise Control:

- In some applications, Cummins engines feature cruise control functionality. This allows the driver or operator to set a desired speed for the vehicle, and the engine control system will work to maintain that speed automatically.

Load Sensing:

- Cummins Engine Speed Control systems are designed to respond to changes in load conditions. Whether the engine is powering a vehicle, generator, or industrial equipment, the control system adapts to load variations to ensure optimal performance.

Fuel Injection Control:

- Efficient fuel injection is crucial for maintaining the desired engine speed. Cummins Engine Speed Control systems manage the timing and quantity of fuel injection to achieve optimal combustion and control the engine speed effectively.

Diagnostic and Monitoring Features:

- Many Cummins Engine Speed Control systems come equipped with diagnostic and monitoring features. These features help identify issues, optimize performance, and facilitate maintenance by providing real-time data and fault codes.

Technical Details:

| Seller SKU: | HQCESC2 |

|---|---|

| Condition: | New |

| Origin: | Nigeria |

| Availability: | In Stock |

| Minimum order quantity: | 1 |

| Date first listed on Zandaux: | Dec 19, 2023 |

Cummins Engine Speed Control is a critical component in diesel engines that helps regulate and maintain the optimal operating speed of the engine. Controlling the engine speed is essential for ensuring efficient performance, fuel economy, and overall durability of the engine.

Electronic Control Module (ECM):

- Cummins engines are equipped with an Electronic Control Module (ECM) that serves as the brain of the engine control system. The ECM processes information from various sensors and uses algorithms to control critical engine parameters, including speed.

Speed Sensors:

- Cummins engines are equipped with speed sensors that continuously monitor the rotational speed of the engine. These sensors provide real-time data to the ECM, allowing it to make rapid adjustments to maintain the desired speed.

Actuators:

- Actuators are devices that respond to signals from the ECM by adjusting the engine components to achieve the desired speed. In the context of speed control, actuators may control fuel injection, air intake, or other parameters affecting engine speed.

Governors:

- Cummins Engine Speed Control systems often include governors, which are mechanical or electronic devices designed to regulate the speed of the engine. Governors can adjust the fuel delivery or airflow to maintain a consistent speed under varying load conditions.

Cruise Control:

- In some applications, Cummins engines feature cruise control functionality. This allows the driver or operator to set a desired speed for the vehicle, and the engine control system will work to maintain that speed automatically.

Load Sensing:

- Cummins Engine Speed Control systems are designed to respond to changes in load conditions. Whether the engine is powering a vehicle, generator, or industrial equipment, the control system adapts to load variations to ensure optimal performance.

Fuel Injection Control:

- Efficient fuel injection is crucial for maintaining the desired engine speed. Cummins Engine Speed Control systems manage the timing and quantity of fuel injection to achieve optimal combustion and control the engine speed effectively.

Diagnostic and Monitoring Features:

- Many Cummins Engine Speed Control systems come equipped with diagnostic and monitoring features. These features help identify issues, optimize performance, and facilitate maintenance by providing real-time data and fault codes.

No reviews

Related Items